A new generation of oscillating shear lines is redefining coil cutting efficiency and flexibility across multiple industries. Designed for processing high-strength steel (HSS), cold rolled steel (CRS), hot rolled steel (HRS), and aluminum, these lines are capable of handling widths of up to 2,500mm and thicknesses ranging from 0.2 to 4.0mm, making them a versatile solution for manufacturers with diverse material requirements.

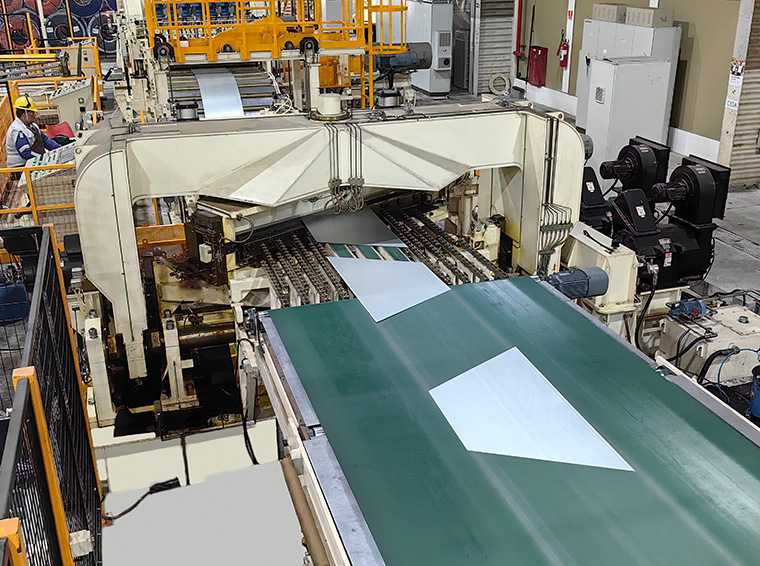

Unlike conventional straight-cut shear lines, oscillating shear technology introduces a dynamic cutting angle range of 0° to 35°. This innovation enables multi-angle cutting, a feature particularly valuable for producing complex workpieces that demand higher dimensional precision. Manufacturers in the automotive, appliance, and construction sectors are already recognizing the impact of this advancement, as it allows faster adaptation to product variations without sacrificing accuracy.

Another key innovation is the Stop/Rotary Oscillating dual-mode cutting system, which provides both stability and speed. The stop shear mode ensures precise fixed-angle cuts, while the rotary oscillating mode allows continuous, high-speed cutting with minimal interruption. This dual approach addresses industry demands for both accuracy and throughput, marking a significant step forward compared with traditional cutting technologies.

With a maximum operating speed of 80 meters per minute, oscillating shear lines dramatically shorten production cycles. This increase in line speed not only boosts output capacity but also enables manufacturers to respond more rapidly to market demand. The ability to achieve higher productivity without compromising cut quality is proving to be a game-changer for competitive industries.

In addition to speed and flexibility, oscillating shear lines are engineered for efficiency. Their advanced cutting mechanics reduce material loss during processing, lowering overall production costs and improving yield. Compared with the ROI of conventional straight-shear systems, these lines demonstrate superior value—particularly for companies embracing smart and green manufacturing practices. By minimizing waste and optimizing resource utilization, oscillating shear technology aligns closely with global sustainability goals.

The introduction of oscillating shear lines marks a milestone in coil processing. As industries move toward greater customization, efficiency, and environmental responsibility, this technology provides a critical tool to address current manufacturing challenges. Its versatility across materials, precision in execution, and efficiency in production cycles position it as an essential asset for manufacturers striving to stay ahead in a highly competitive global market.

Teikti klientams tikslius lakštų pjovimo sprendimus ir padėti kurti išmaniuosius metalo apdirbimo centrus.

Gamykla Japonijoje

Gamykla Japonijoje

ADRESAS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japonija

Japonijos vietinė rinka:+81 53-425-5331

Japonijos vietinė rinka:+81 53-425-5331

Gamykla Kinijoje

Gamykla Kinijoje

ADRESAS

265 Yixian Road, Deqing, Zhejiang, Kinija

Užjūrio rinka:+86 572-883-2016

Užjūrio rinka:+86 572-883-2016